Ultrasonic Wire Cleaning Systems for Lubricant Removal or Annealing

Wire cleaning is a difficult task when compared to most traditional ultrasonic cleaning applications. The contaminant, typically a sodium or calcium-based dry lubricant, is pressed deeply into the surface of the material as it passes through the wire drawing process. In some cases, liquid lubricants may also be used which are less difficult to remove. Not only are the contaminants highly bonded to the surface, wire manufacturing processes are performed at elevated speeds, which reduces the contact time between the wire and the cleaning operation.

To overcome the difficulties associated with wire cleaning operations, Zenith developed 2 high-speed wire cleaning systems as well as a pre-annealing cleaning system designed to remove contaminants prior to annealing of multiple wires. These systems include an extended ultrasonic cleaning chamber, an ultrasonic or spray rinsing chamber, and high-speed air drying systems to clean wire with the most stubborn contaminants at high rates of speed. Additional features, such as an additional blow-off operation between cleaning and rinsing areas, conserve the use of water, and ensure perfect results with little equipment maintenance.

In the past, manufacturers of wire relied on spray washing systems to address the removal of oils and particles from the product. However, there are limitations to these designs. The primary complaint of customers owning spray washing systems for wire is the consumption of water, leaking seals and spray which contaminates the environment, and continuous spray nozzle maintenance. All of these issues are non-existent on a Zenith SSW wire cleaning system.

A Zenith Ultrasonic Wire Cleaning System overcomes the limitations of a spray washing system by utilizing the precision, low-maintenance cleaning capabilities of ultrasonic cleaning technology. By incorporating this technology, and extending the length of the ultrasonic cleaning chamber, dry and liquid wire lubricants are quickly and effectively removed.

SSW-690 Wire Cleaning System

- Designed for speeds from 50-250FPM.

- Wire diameters up to 1/2″

- Smaller footprint than our other wire cleaning systems.

- Ultrasonic cleaning, spray rinsing, and drying included.

- All stainless steel construction.

- Internally-mounted components with easy access for service and maintenance.

- Color touch-screen HMI and on-board PLC control system.

- Internally and externally-welded tanks with support bands for superior strength.

- Designed for speeds up to 250 ft/min

- Easy-load design

- Capable of cleaning multiple strands depending upon distance between strands.

- UHMW guide blocks.

- Designed for 24/7 continuous duty operation.

- 304 polished stainless steel tubular framing.

- 316L stainless steel tanks & seamless tabletop.

- Stainless filter housings & filter pump.

- Color touch-screen HMI and PLC control system.

- Permits interfacing with existing drawing equipment.

- UHPD CROSSFIRE Multiple Frequency Ultrasonics with erosion protection.

- Low liquid level protection.

- Ultrasonic power intensity controls.

- Compressed air drying system.

- High-speed immersion heating systems with digital controllers.

- Closed-cell fluoride/chloride-free insulation.

- NEMA4X control enclosures.

- 316L easy-access external latching panels.

- Internal components easily accessed from the front of the system.

- Industrial-grade controls, no membrane switches.

- Stainless steel hinged covers.

- Light tower to indicate system operating conditions.

- Automatic Liquid Level Maintenance & Filling Systems.

- Detergent Injection.

- High-head Pump Drain Systems.

- Rinse Overflow Capture Tanks & Automatic Drain Systems (upgrade to the pump drain option).

- Automatic Rinse Water Quality Maintenance.

- Water Purification & Deionization Systems for zero residue cleaning results.

- Waste neutralization systems for disposing of acidic or alkaline wastes.

- Wastewater evaporators to reduce waste disposal costs.

- Interlocked process area covers.

- Filter system Service Alert Switches.

- Automatic Pump Backup systems.

SSW-690 is the part number for this machine.

Press HERE to download our SSW-960 brochure.

SSW-960 Wire Cleaning System

- Designed for speeds up to 400 ft/min.

- Longer cleaning chamber provides additional contact time for improved cleaning results.

- Wire diameters up to 1/2″

- Smaller footprint than our other wire cleaning systems.

- Ultrasonic cleaning, ultrasonic rinsing, and drying included.

- All stainless steel construction.

- Internally-mounted components with easy access for service and maintenance.

- Color touch-screen HMI and on-board PLC control system.

- Internally and externally-welded tanks with support bands for superior strength.

- Easy-load design.

- Longer cleaning chamber than the SSW-690 for increased ultrasonic contact time.

- Capable of cleaning multiple strands depending upon distance between strands.

- UHMW guide blocks.

- Designed for 24/7 continuous duty operation.

- 304 polished stainless steel tubular framing.

- 316L stainless steel tanks & seamless tabletop.

- Stainless filter housings & filter pump.

- Color touch-screen HMI and PLC control system.

- Permits interfacing with existing drawing equipment.

- UHPD CROSSFIRE Multiple Frequency Ultrasonics with erosion protection.

- Low liquid level protection.

- Ultrasonic power intensity controls.

- Compressed air drying system.

- High-speed immersion heating systems with digital controllers.

- Closed-cell fluoride/chloride-free insulation.

- NEMA4X control enclosures.

- 316L easy-access external latching panels.

- Internal components easily accessed from the front of the system.

- Industrial-grade controls, no membrane switches.

- Stainless steel hinged covers.

- Light tower to indicate system operating conditions.

- Automatic Liquid Level Maintenance & Filling Systems.

- Detergent Injection.

- High-head Pump Drain Systems.

- Rinse Overflow Capture Tanks & Automatic Drain Systems (upgrade to the pump drain option).

- Automatic Rinse Water Quality Maintenance.

- Water Purification & Deionization Systems for zero residue cleaning results.

- Waste neutralization systems for disposing of acidic or alkaline wastes.

- Wastewater evaporators to reduce waste disposal costs.

- Interlocked process area covers.

- Filter system Service Alert Switches.

- Automatic Pump Backup systems.

SSW-960 is the part number for this machine.

Press HERE to download our SSW-960 brochure.

SSW-132 Wire Cleaning System

- Designed for speeds up to 700FPM (depending upon lubricant type).

- Longer cleaning chamber provides additional contact time for improved cleaning results.

- Wire diameters up to 1/2″

- Smaller footprint than our other wire cleaning systems.

- Ultrasonic cleaning, ultrasonic rinsing, and drying included.

- All stainless steel construction.

- Internally-mounted components with easy access for service and maintenance.

- Color touch-screen HMI and on-board PLC control system.

- Internally and externally-welded tanks with support bands for superior strength.

- Easy-load design.

- Longer cleaning chamber than the SSW-960 for increased ultrasonic contact time.

- Capable of cleaning multiple strands depending upon distance between strands.

- UHMW guide blocks.

- Designed for 24/7 continuous duty operation.

- 304 polished stainless steel tubular framing.

- 316L stainless steel tanks & seamless tabletop.

- Stainless filter housings & filter pump.

- Color touch-screen HMI and PLC control system.

- Permits interfacing with existing drawing equipment.

- UHPD CROSSFIRE Multiple Frequency Ultrasonics with erosion protection.

- Low liquid level protection.

- Ultrasonic power intensity controls.

- Compressed air drying system.

- High-speed immersion heating systems with digital controllers.

- Closed-cell fluoride/chloride-free insulation.

- NEMA4X control enclosures.

- 316L easy-access external latching panels.

- Internal components easily accessed from the front of the system.

- Industrial-grade controls, no membrane switches.

- Stainless steel hinged covers.

- Light tower to indicate system operating conditions.

- Automatic Liquid Level Maintenance & Filling Systems.

- Detergent Injection.

- High-head Pump Drain Systems.

- Rinse Overflow Capture Tanks & Automatic Drain Systems (upgrade to the pump drain option).

- Automatic Rinse Water Quality Maintenance.

- Water Purification & Deionization Systems for zero residue cleaning results.

- Waste neutralization systems for disposing of acidic or alkaline wastes.

- Wastewater evaporators to reduce waste disposal costs.

- Interlocked process area covers.

- Filter system Service Alert Switches.

- Automatic Pump Backup systems.

SSW-132 is the part number for this machine.

Press HERE to download our SSW-132 brochure.

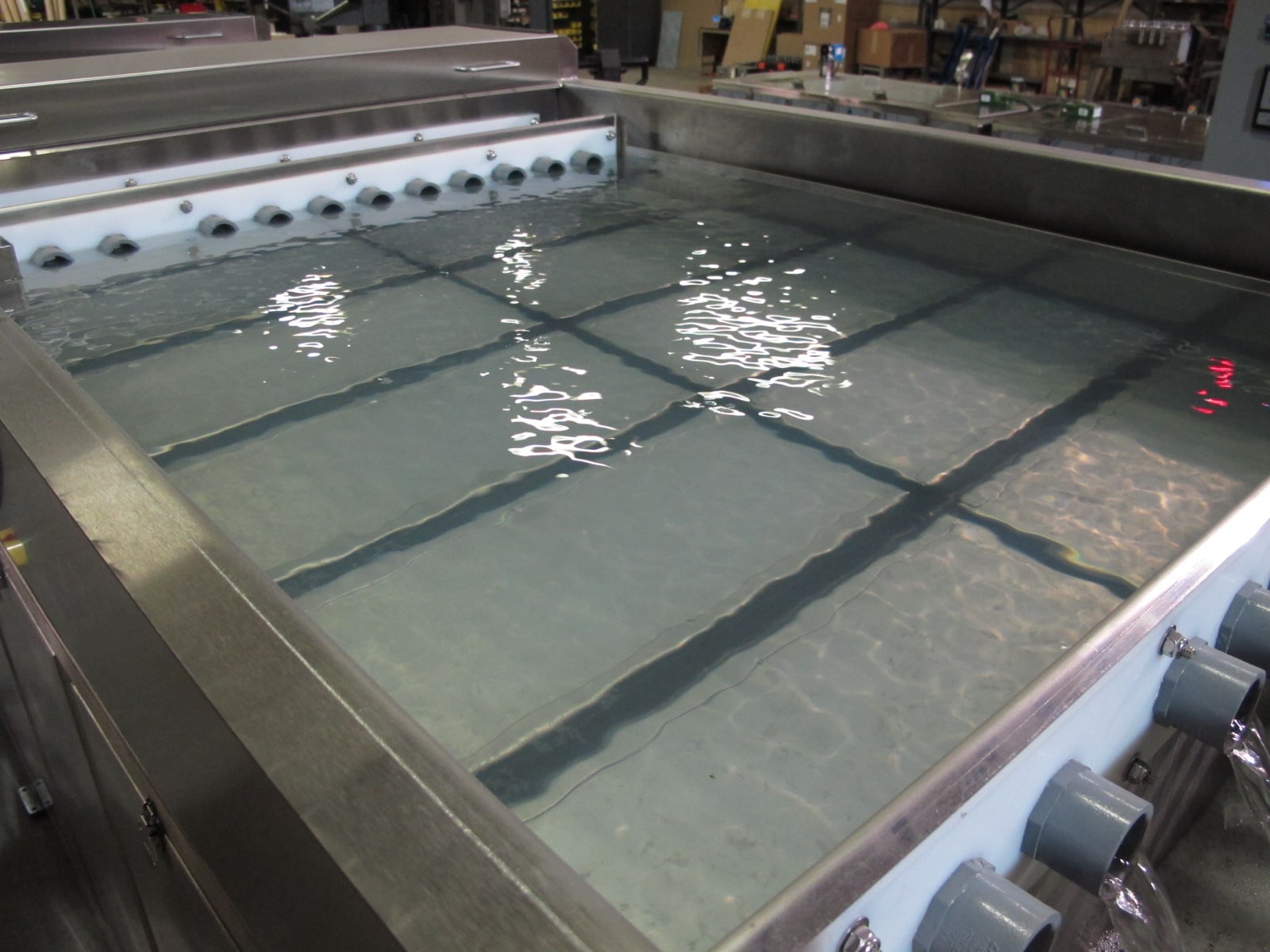

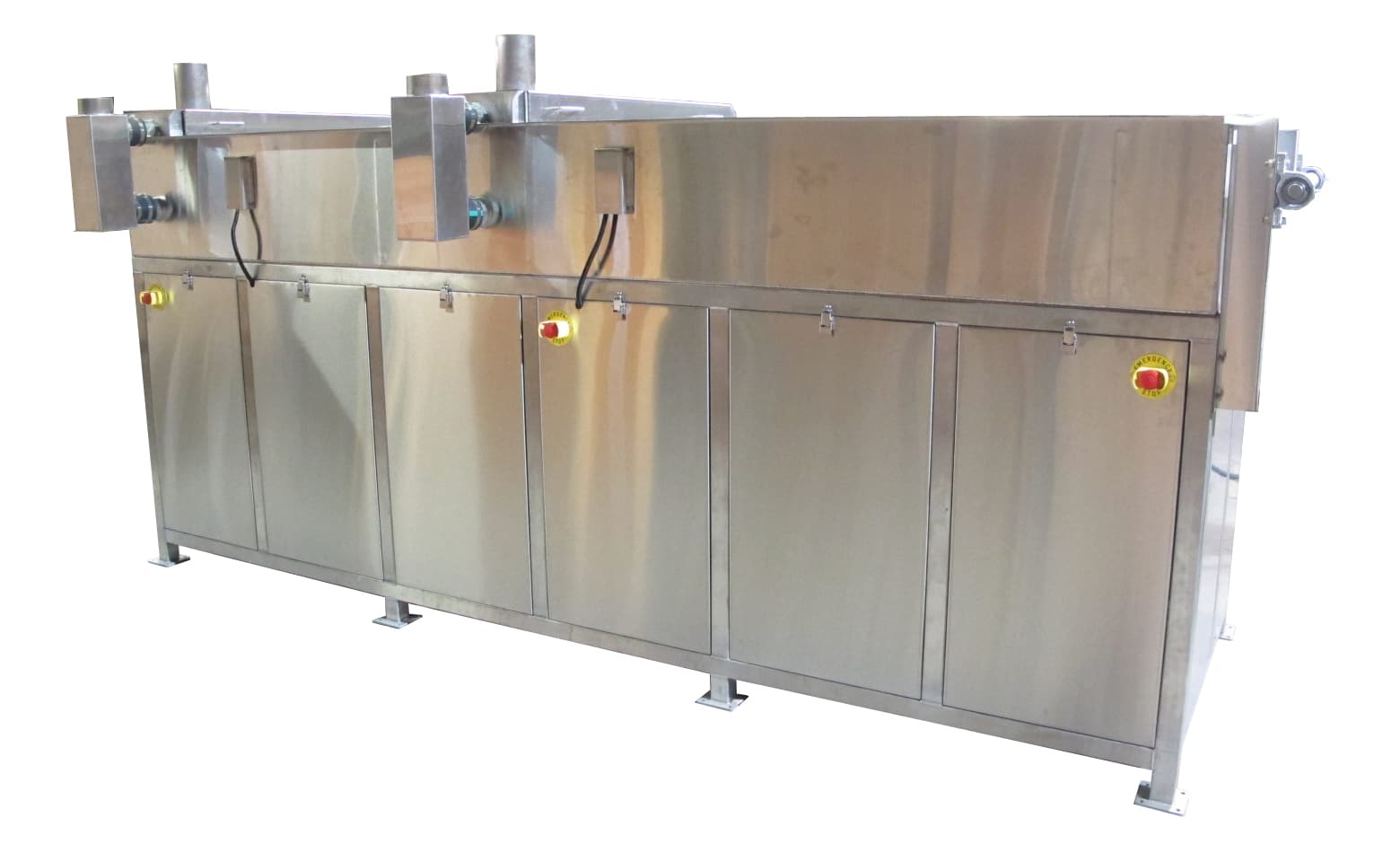

MWPA Annealing Wire Cleaning Systems

- Designed for multi-wire cleaning at low speeds prior to wire entering an annealing furnace.

- Long ultrasonic cleaning and rinsing chambers remove contaminants to prevent wire discoloration and reduce furnace maintenance.

- Wire diameters up to 3.8″

- Ultrasonic cleaning, ultrasonic rinsing, and drying included.

- All stainless steel construction.

- Internally-mounted components with easy access for service and maintenance.

- Color touch-screen HMI and on-board PLC control system.

- Internally and externally-welded tanks with support bands for superior strength.

- Easy-load design.

- 3-sided overflow of surface contaminants.

- Designed for the simultaneous cleaning of up to 12 strands of wire.

- UHMW guide blocks with specialized flow blocking technology.

- Designed for 24/7 continuous duty operation.

- 304 polished stainless steel tubular framing.

- 316L stainless steel tanks & seamless tabletop.

- Stainless filter housings & filter pump.

- Color touch-screen HMI and PLC control system.

- Permits interfacing with existing drawing equipment.

- UHPD CROSSFIRE Multiple Frequency Ultrasonics with erosion protection.

- Low liquid level protection.

- Ultrasonic power intensity controls.

- Compressed air drying system.

- High-speed immersion heating systems with digital controllers.

- Closed-cell fluoride/chloride-free insulation.

- NEMA4X control enclosures.

- 316L easy-access external latching panels.

- Internal components easily accessed from the front of the system.

- Industrial-grade controls, no membrane switches.

- Stainless steel hinged covers.

- Light tower to indicate system operating conditions.

- Automatic Liquid Level Maintenance & Filling Systems.

- Detergent Injection.

- High-head Pump Drain Systems.

- Rinse Overflow Capture Tanks & Automatic Drain Systems (upgrade to the pump drain option).

- Automatic Rinse Water Quality Maintenance.

- Water Purification & Deionization Systems for zero residue cleaning results.

- Waste neutralization systems for disposing of acidic or alkaline wastes.

- Wastewater evaporators to reduce waste disposal costs.

- Interlocked process area covers.

- Filter system Service Alert Switches.

- Automatic Pump Backup systems.

SSW-960 is the part number for this machine.

Press HERE to download the MWPA Wire Cleaner brochure.