Ultrasonic Cleaners for Every Application

Providing Ultrasonic Cleaners for Your Business Needs

Zenith Ultrasonics provides ultrasonic cleaners for businesses. When precision matters and traditional cleaning methods fall short, ultrasonic cleaning technology delivers exceptional results. From delicate medical instruments to heavy industrial parts, these powerful systems are revolutionizing how businesses approach cleaning challenges across countless industries. Whether dealing with stubborn contaminants, complex geometries, or high-volume cleaning requirements, understanding how ultrasonic cleaners work and their benefits can help you make informed decisions for your business operations.

What Are Ultrasonic Cleaners?

Ultrasonic cleaners use high-frequency sound waves to create microscopic bubbles in a cleaning solution. This process, called cavitation, generates intense scrubbing that reaches into every crevice, hole, and surface irregularity of submerged items. The bubbles form and collapse rapidly, creating powerful cleaning forces that remove dirt, grease, oils, and other contaminants without physical scrubbing or harsh chemicals. These systems consist of a tank filled with cleaning solution, ultrasonic transducers that generate sound waves, and controls for adjusting frequency, temperature, and cleaning time. The cleaning process is gentle yet thorough, making it ideal for items that traditional cleaning methods could damage.

Benefits of Ultrasonic Cleaning Systems

Ultrasonic cleaning offers numerous advantages over conventional cleaning methods, making it an attractive solution for businesses seeking efficiency and reliability. Here are the following benefits you can expect:

- Superior Cleaning Performance: The microscopic bubbles reach areas that brushes, sprays, and other cleaning methods cannot access. This includes blind holes, cracks, internal passages, and complex geometries that would otherwise require disassembly for proper cleaning.

- Time and Labor Savings: Parts cleaners using ultrasonic technology can clean multiple items simultaneously, significantly reducing processing time. Most cleaning cycles take minutes rather than hours, freeing up valuable labor for other tasks.

- Consistent Results: Unlike manual cleaning, ultrasonic systems always deliver consistent cleaning quality. The automated process eliminates human variables, ensuring reliable results across all cleaning cycles.

- Environmentally Friendly: These systems often require less cleaning solution and can work effectively with biodegradable detergents, reducing environmental impact compared to harsh chemical cleaning processes.

- Cost-Effective Operation: While initial investment varies, the long-term operational costs are typically lower due to reduced labor requirements, minimal chemical usage, and extended equipment life.

Who Benefits from Ultrasonic Cleaning?

Industrial ultrasonic cleaners serve various industries and applications, each with specific cleaning challenges that benefit from this technology. Below are some of the top industries these systems work with:

- Manufacturing Industries: Automotive, aerospace, and electronics manufacturers use these systems to clean precision parts, removing machining oils, flux residues, and manufacturing debris before assembly or finishing processes.

- Medical and Dental Facilities: Healthcare providers rely on ultrasonic cleaning to prepare surgical instruments, dental tools, and medical devices for sterilization, ensuring complete removal of biological contaminants.

- Jewelry and Watchmaking: Delicate items requiring gentle yet thorough cleaning benefit from ultrasonic technology’s non-abrasive nature, restoring shine without risk of damage.

- Restoration and Maintenance: Antique restoration, firearms cleaning, and equipment maintenance operations use ultrasonic cleaners to remove years of accumulated dirt and corrosion from valuable items.

- Research and Laboratory Settings: Scientific instruments, glassware, and precision equipment require contamination-free surfaces that ultrasonic cleaning reliably provides.

Why Choose Zenith Ultrasonics?

Zenith Ultrasonics stands apart in the ultrasonic cleaning industry through our commitment to quality, innovation, and customer service. Our expertise helps businesses find the right cleaning solution for their specific needs. Consider the following reasons why customers trust us:

- Proven Track Record: With years of experience designing and manufacturing automated ultrasonic cleaners, we understand different industries’ unique challenges and provide tailored solutions that deliver results.

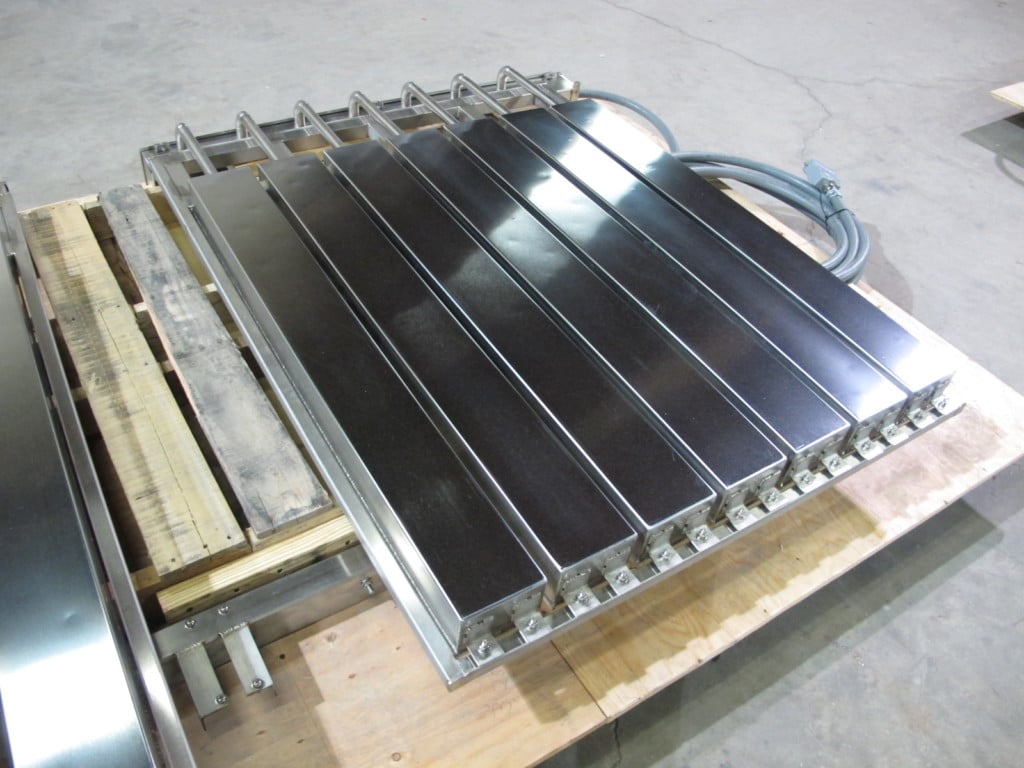

- Comprehensive Product Range: Our product line covers applications of all sizes, from compact benchtop units to large industrial systems. We offer standard models and custom configurations to meet specific requirements.

- Technical Support: Our team provides ongoing technical assistance, helping customers optimize their cleaning processes and troubleshoot any issues. We’re committed to your success beyond the initial purchase.

- Quality Construction: Our ultrasonic cleaners are built to withstand demanding industrial environments, using high-quality components and robust construction that ensures reliable operation and long service life.

- Training and Documentation: We provide thorough training and comprehensive documentation to help your team maximize the benefits of ultrasonic cleaning technology from day one.

Transform Your Cleaning Process Today

Ultrasonic cleaning technology offers a powerful solution for businesses seeking superior cleaning results, improved efficiency, and cost-effective operations. The combination of gentle yet thorough cleaning action makes these systems invaluable across numerous industries and applications. Ready to discover how ultrasonic cleaners can benefit your operation? Contact Zenith Ultrasonics today to discuss your specific cleaning challenges and explore the right ultrasonic cleaning solution for your needs. Our experienced team is here to help you achieve the cleaning performance your business demands.