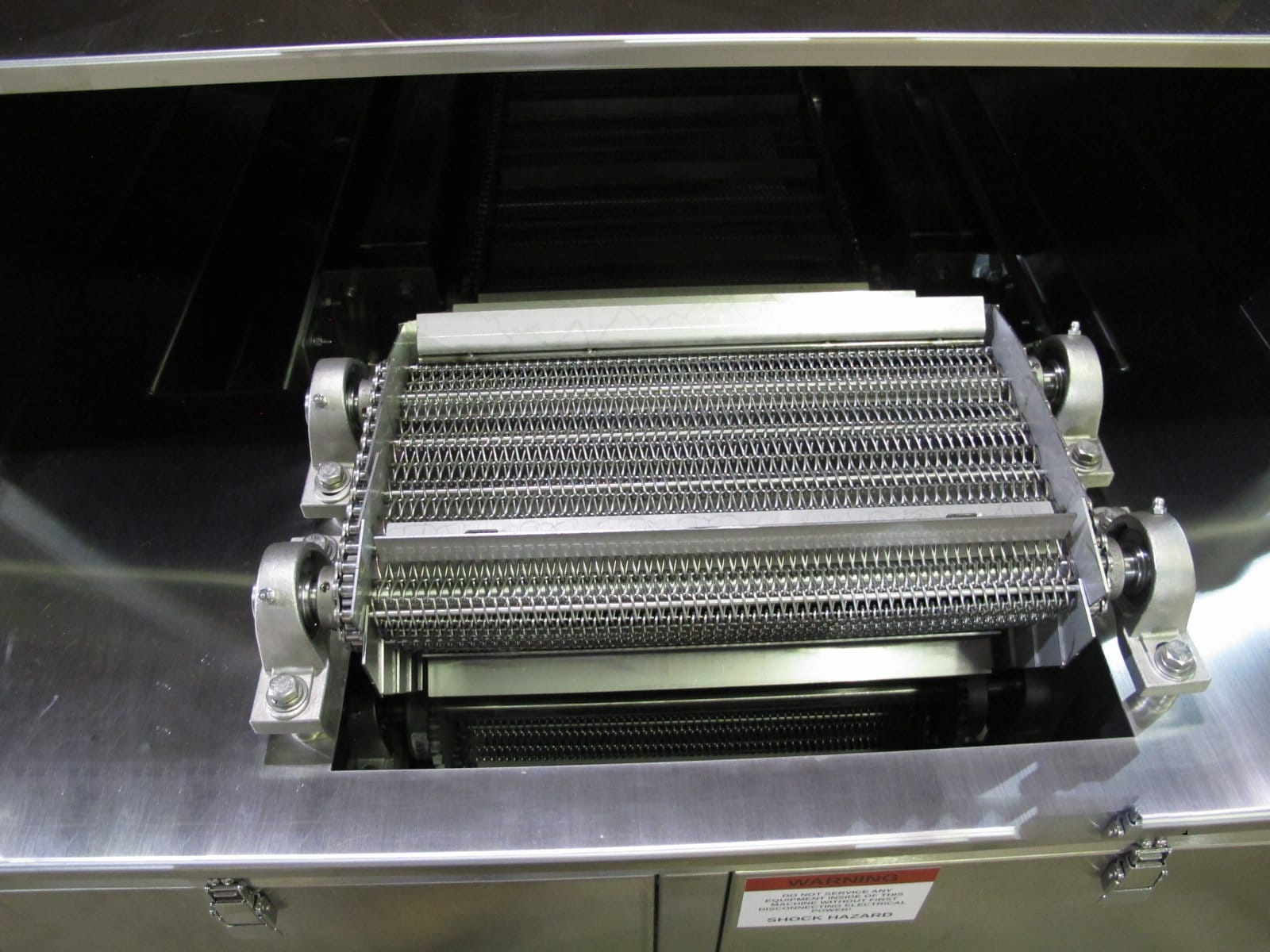

Conveyor Ultrasonic Cleaner with Spray Washer Convenience

The Orbit Conveyor Ultrasonic Cleaner is a clean/rinse/dry system that was designed for industrial or ultra-critical cleaning applications. The system eliminates the needs for baskets which are used in a traditional ultrasonic cleaning system Parts are placed onto a moving conveyor belt directly, and are moved through the system continuously or intermittently depending on your needs. A combination of several cleaning, rinsing, and drying technologies are included to ensure that parts are perfectly clean and residue free. Parts exit the system at the opposite end and can be deposited into bulk collection containers or simply removed using other available means. Your operators will never have to load or unload parts from processing baskets or transfer empty baskets back to the loading area in the Orbit conveyor ultrasonic system.

ORBIT Cleaning System Specifications

- 14.5″ conveyor belt width, other sizes are available.

- Variable Frequency Drive for conveyor speed adjustments.

- High-power CROSSFIRE Multiple Frequency Ultrasonic Systems in both cleaning and rinsing chambers.

- Universal stainless steel filtration systems that accept standard or “absolute” filter cartridges.

- All stainless steel construction.

- Includes submersion ultrasonic cleaning, spray cleaning, submersion ultrasonic rinsing and spray rinsing on all parts passing through the system.

- Devices to reduce detergent drag-out from the cleaning chamber to rinsing chamber extends the life of rinse water and deionization resins if the deionization system option is purchased.

- 5-color light tower for operator alerts

- Stainless steel process area covers.

- Tubular stainless steel support frame and conveyor belting.

- Industrial-grade components and controls for continuous-duty operation.

- Color touch-screen HMI and PLC control system for the ultimate in operational convenience.

- Internally and externally-welded tanks with support bands for superior strength.

- Orbit 1450: Complete conveyor ultrasonic clean/rinse/dry system

- Custom sizes are available

- 304 polished stainless steel tubular framing

- 316L stainless steel tanks & seamless tabletop

- Stainless universal filter housings & filter pump on both cleaning and rinsing chambers.

- Color touch-screen HMI and PLC control system.

- CROSSFIRE Multiple Frequency Ultrasonic System in both cleaning and rinsing chambers.

- Ultrasonic power intensity controls

- Detergent Drag-out Prevention System.

- Adjustable conveyor speed.

- High-speed immersion heating systems with digital temperature controllers.

- Closed-cell fluoride/chloride-free insulation

- NEMA4X control enclosures

- 316L easy-access external latching panels.

- Internal components easily accessed from the front of the system.

- Industrial-grade controls, no membrane switches.

- Stainless steel process area covers.

- Stainless steel conveyor belt or custom fixture trays.

- All stainless steel bearings and UHMW conveyor supports.

- Spray cleaning and rinsing systems.

- Air-knife drying system with optional heated drying tunnel also available.

- 5-color light tower for operator feedback.

- Processes many parts faster than a batch-type multi-stage ultrasonic cleaner.

- Slope-bottom processing tanks for improved filtration performance.

- Surface Skimming to prevent re-deposition of contaminants onto parts when removed from the tank.

- Anti-erosion Ultrasonic Coatings to extend transducer life.

- Process Area Enclosures with or without HEPA filtration & Exhaust Systems.

- Automatic Liquid Level Maintenance & Filling Systems.

- Detergent Injection.

- High-head Pump Drain Systems.

- Rinse Overflow Capture Tanks & Automatic Drain Systems (upgrade to the pump drain option).

- Automatic Rinse Water Quality Maintenance.

- Water Purification & Deionization Systems for zero residue cleaning results.

- Casters for easy relocation

- Heated drying tunnel with high-volume air flow.

ORBIT 1450 is the part number for our standard 14.5″ Orbit cleaning system. Part numbers for other sizes will be determined during the quotation process.

Download the Orbit brochure HERE.