Selecting the proper ultrasonic cleaning fluid is as important as selecting the proper ultrasonic cleaning frequency!

Although most ultrasonic equipment manufacturers would like you to believe that it is the equipment that does all of the work, nothing could be further from the truth. Using the proper ultrasonic cleaning fluids for a given application is the 2nd most important part of a successful ultrasonic process. The detergent selected must be able to quickly reduce the bond between the contaminant and the parts being cleaned to a level where existing ultrasonic energy can easily remove the contamination. If the detergent lacks this capability, parts will only be cleaned where ultrasonic energy is strong enough to remove the contamination.

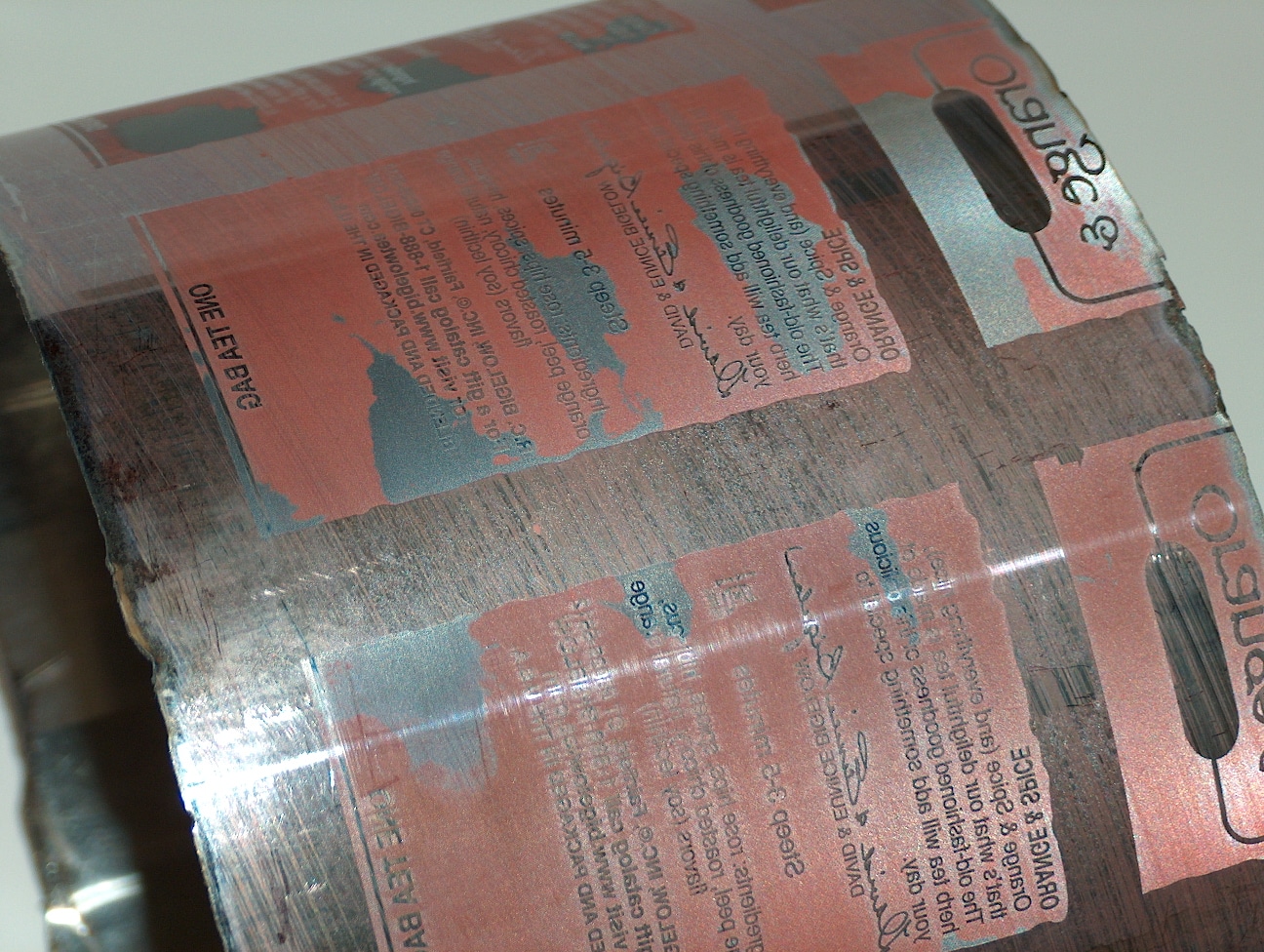

The neighboring photos depict 2 parts which were ultrasonically cleaned. The top item was cleaned with a detergent that was not appropriate for the application, and was only partially cleaned whereas the bottom photo depicts the same part cleaned in a cleaning fluid that had the ability to reduce the contaminant-to-part bond. By looking closely at the part which was only partially cleaned, you can see that SOME of the contamination was removed, and these locations align with the standing waves produced by the ultrasonic system in use.

When the ultrasonic cleaning fluid is perfectly matched to the application, the contaminant should be removed immediately when the part is lowered into the ultrasonic bath, preferably in large clouds, from every area of the part. Ultrasonic cleaners will not blast the contaminant from the surface of the part, but will rather lift the contaminant from the surface in thin layers. If you do not see the contaminant lifting virtually immediately, chances are good that the cleaning agent is not a good match for the application.

Simple Cleaning Agent Compatibility Tests

The only way to determine if a cleaning agent is appropriate for the application is by testing in the ultrasonic cleaner. However, a simple test using the cleaning agent on a white towel can provide an initial indication of whether or not to fluid might be effective. Place a small amount of the detergent mixture on a white towel, and GENTLY wipe the surface. DO NOT add excessive pressure. If you find that the contaminants are found on the white towel, and are easily removed, chances are good that the cleaning agent will be effective for the application. If this is the case, try the detergent in the ultrasonic cleaner to see how it performs.

Compatibility with Material of Construction

One must also consider the material of construction of the parts being cleaned. Some metals, such as aluminum, require special cleaning agents that are multi-metal safe. These fluids are readily available from Zenith, or other cleaning agent manufacturers. Unfortunately, since these cleaners are rather mild, or contain inhibitors to prevent damage to aluminum parts, they are gentler and are not typically capable of removing stubborn contamination unless specifically formulated for the application.

Zenith Cleaning Fluid Selection

Zenith Ultrasonics has been in the cleaning business since 1937 and has decades of experience in determining the best cleaning agents for a given application. In the vast majority of cases, a single cleaning agent sold by Zenith can be used for many different cleaning applications and this limits the required number of agents which our customers need to choose from. We have cleaners for removing most industrial contaminants and will test your parts in our cleaning agents before an equipment purchase is made to ensure that you are completely satisfied with the results before a significant investment in equipment is made.

See the links below for additional information on test cleaning and our line of ultrasonic cleaning fluids.