What are ultrasonic cleaners used to clean?

Ultrasonic cleaners are used to clean virtually any newly-manufactured metal part, from industrial components to medical implant devices and everything in between. They can can also be used to clean parts which were already in use and require that contaminants on its surfaces be removed. The list is virtually endless, but here is a partial list of some of the more common ultrasonic cleaning applications:

- Oil, coolant, and metal chip removal from machined components

- Burned carbons

- Rust

- Coatings

- Waxes

- Grease

- Zero-residue Precision Parts

- Polishing and Lapping Compound Removal

- Grinding and Cutting Residue Removal

- Plastic Injection Molds

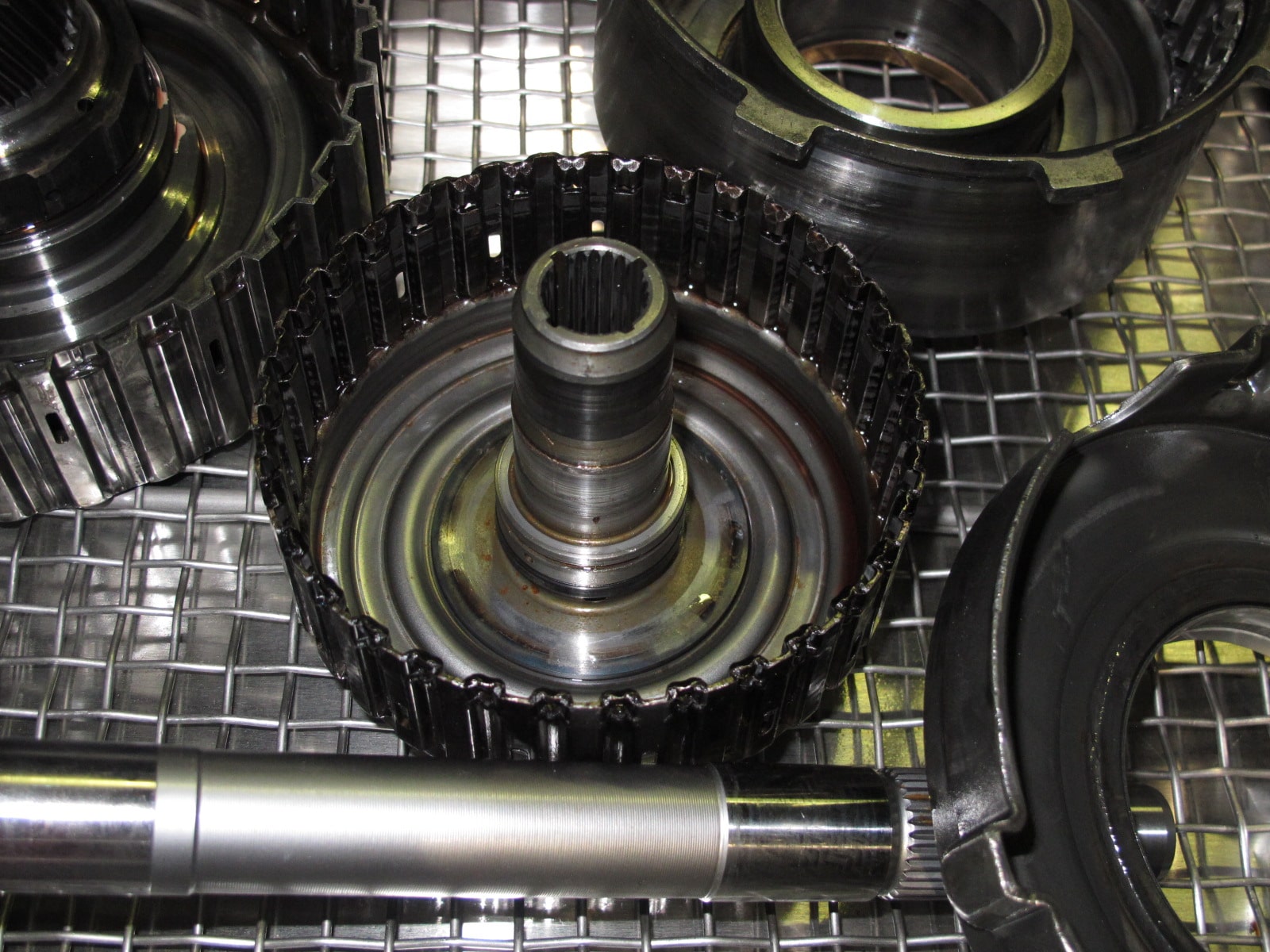

- Automotive and Aviation Components

- Venetian Blinds and Window Coverings

- Wire Drawing Lubricant Removal and pre-annealing cleaning

- Progressive Stamped Metal Strip

- Silicon Wafers

- Optics and Lens Cleaning Prior to Coating Operations

- Laser Components and Lenses

- Laser-engraved Anilox Printing Rollers

- Coating Removal Applications

- Electronic Boards and Components

- Dental Devices

- Rust & Oxidation Removal

- Weapons Cleaning

- Paint Mixing Containers

- Medical Implant Devices

- Fishing Reel Components

- Degassing of Hydraulic Fluids

- Aerospace Components

- Diesel and Gasoline Fuel Injectors

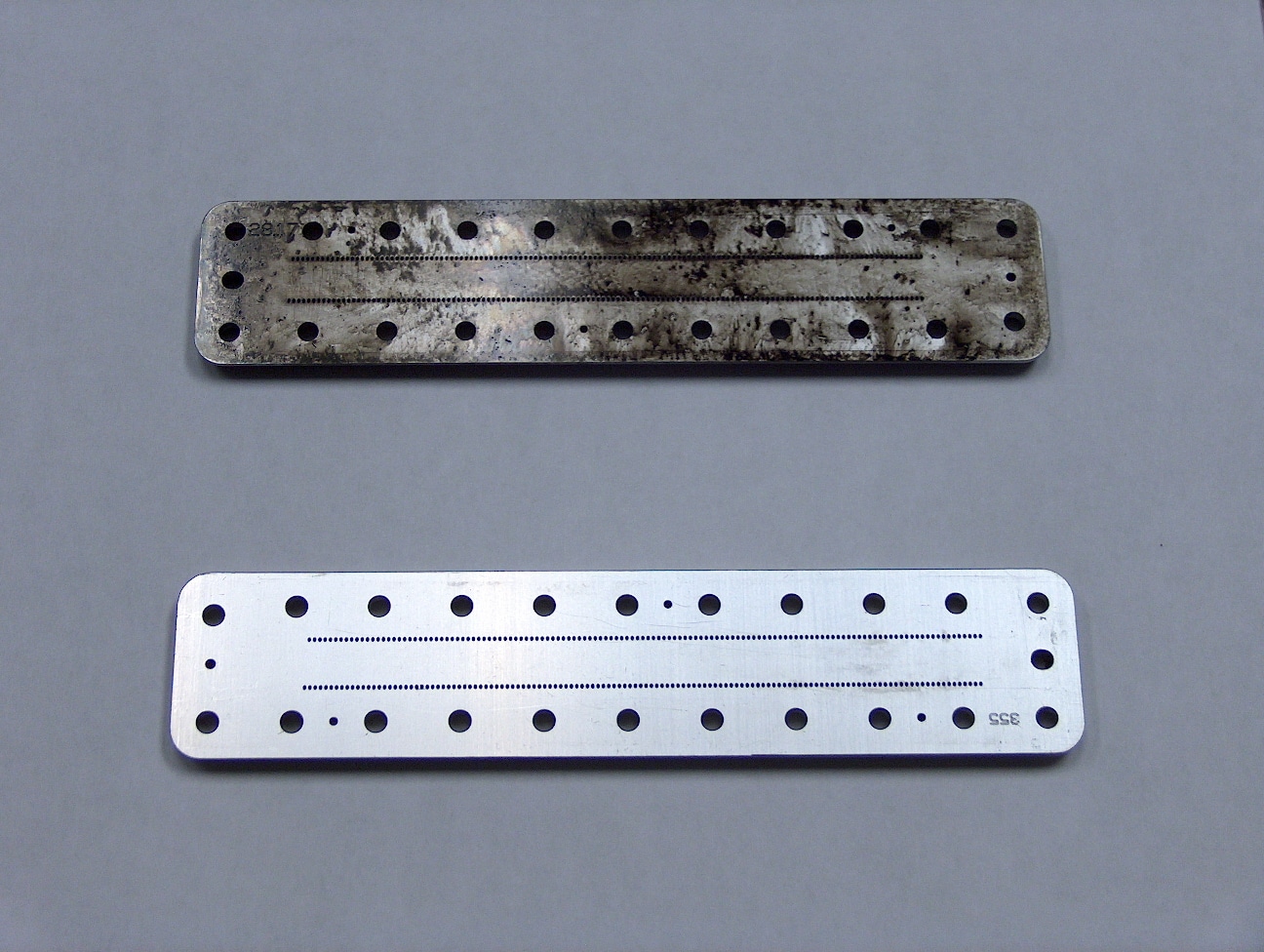

- PC Board Stencils

- Fluorescent Penetrant Inspection (FPI)

- Metal Parts Prior to Plating or PVD/CVD Coating Operations

- Fine Mechanical Assembly Cleaning

- Cereal Molding Equipment

- Metal Fine Removal

- Radioactive Decontamination of Metal Components

- Complex Valve Assembly Cleaning

- Fiber Optics

- Spinnerets

- Soldering Flux Removal

- Automotive Transmissions

- Metal Stampings

- Solenoid Valve Bodies

- Kevlar Honeycomb

- Stainless Steel Filters

This is a VERY small list of applications which we have addressed at Zenith.

My parts aren’t on the list. Does that mean that ultrasonics won’t clean them?

Not at all. There are thousands of applications that ultrasonic cleaners can address. The key to a successful ultrasonic cleaning use one basic rule; use a detergent that can reduce the bond between the parts and the contaminants that permits the ultrasonic energy to remove it at the wattage provided.

The bottom line is if your parts are made of metal, an ultrasonic cleaner can most likely address your application.

Can plastic parts be cleaned ultrasonically?

This depends upon the hardness of the plastic and the type of contamination you are trying to remove. Plastics tend to dampen ultrasonic energy, especially softer plastics or rubber and this makes the ultrasonic cleaning of plastics more difficult than when cleaning metal components. Having your parts ultrasonically tested is the best way to determine if an ultrasonic cleaner will be effective for your application, and Zenith offers a free-of-charge testing service for this purpose.