Tabletop Ultrasonic Cleaners For Small Cleaning Jobs

If you already have a tabletop ultrasonic cleaner, or many of them, we bet that they will have the following design characteristics:

- Rounded-corner tanks: When you look inside of the tank, the corners are rounded.

- One-piece Design: The generator and cleaning tank are combined into a single object.

- They do not last more than a year or two.

These are both characteristics of “lab-grade “tabletop ultrasonic cleaners, and the tanks used in these systems are actually the same pans you will find at you children’s school cafeteria or all-you-can-eat buffet restaurants. Although these systems have their place and are lower in cost, they have some shortcomings that you should be aware of.

- The tanks on these tabletop ultrasonic cleaners are very thin, and will only last for a long time if the ultrasonic power is rather low, or not used very often. If power is very high, the tank will not last very long due to a side-effect of all ultrasonic cleaners known as cavitational erosion.

- Reliability of this type of tabletop ultrasonic cleaner is lower since the ultrasonic generator is mounted in the same heated space as the ultrasonic cleaning tank. As a result, short-term use is a good policy when using these systems. The biggest complaint we hear from users of these systems is that they cannot be operated for long periods of time or the system is destroyed.

- Most of these systems are imported from overseas.

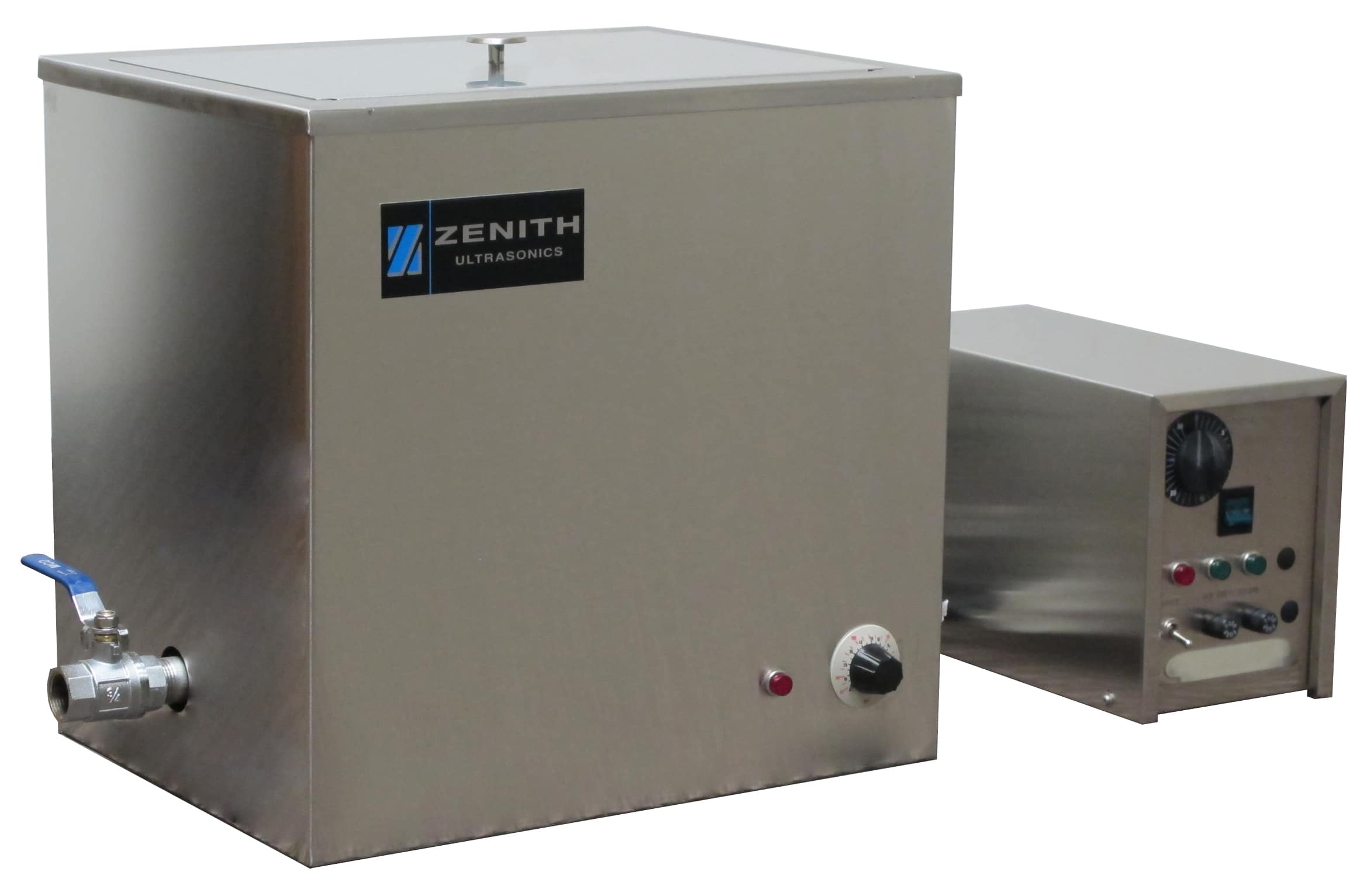

The Zenith tabletop ultrasonic cleaner is very different!

Zenith’s tabletop ultrasonic cleaner is very different:

- Our tabletop ultrasonic cleaners are manufactured of thick material to resist erosion damage and extend tank life.

- Tanks are nitrogen-purged during manufacturing to ensure that all welds penetrate and fill the gaps between metals completely.

- Separate Ultrasonic Generator for the best reliability.

- The ability to operate continuously for many years.

- Will work with loads up to 35 pounds.

Not only will our line of tabletop ultrasonic cleaners work better and last longer, they are available with CROSSFIRE Multiple Frequency Ultrasonics, and our engineers will ensure that the frequencies selection will perfectly match your cleaning application and requirements. 25kHz, 40khz, 80kHz, they are all available.

- 200-1: 12″ x 6″ x 9″ tall.

- 260-2: 12″ x 12″ x 10″ tall.

- 400-1: 14″ x 10″ x 12″ tall.

- 460-1: 20″ x 6″ x 9″ tall.

- 800-2: 20″ x 12″ x 14″ tall.

- 1600-1: 24″ x 24″ x 24″ tall.

- Any size can be manufactured custom with no customization charges.

- Thick-wall 316L nitrogen-purged stainless steel tanks and 316L stainless skirting.

- Separate ultrasonic generator to promote long reliability.

- Ball valve drains.

- Choice of G4-series table-top generator or ORION industrial-grade digital ultrasonic generator.

- Designed for continuous-duty use for many years. Typical life of these systems is 10+ years.

- Includes removable stainless steel cover.

- Load capacity up to 35 pounds.

The 400-1 through 800-2 can be equipped with our optional Mark V Agitation System that will automate the process and provide intermittent or continuous agitation of parts during the cleaning process. Custom agitation systems can be manufactured for any of the other standard sizes or for custom-sized tanks.

- CROSSFIRE Multiple Frequency Ultrasonic Systems.

- Digital or analog heating systems.

- Digital or mechanical cycle timers.

- Processing baskets.

- Custom tank sizes.

- ORION industrial-grade ultrasonic generators for increased power and operational features.

Press HERE to download the Table-top Ultrasonic Cleaners brochure.