Agitating Parts Washers Provide Many Benefits

Moving parts during the ultrasonic cleaning process using agitating parts washers can affect the cleaning results in the following ways:

- Items are scanned through the “hotspots” of ultrasonic energy which are present in all ultrasonic cleaners. This is especially important when cleaning with 25kHz or 40kHz ultrasonic cleaners.

- Blind holes (holes that have no exit hole) are cleaned more effectively.

Damage by ultrasonic attack can be reduced or eliminated on sensitive parts such as highly-polished aluminum, electronics, and other soft metals. - Dirt which is loosened by the ultrasonic action is flushed away from the surface.

Why Scanning Parts is Important

By moving items through the cleaning bands (also known as “hotspots” or “standing waves) produced by every ultrasonic cleaner, parts are more evenly exposed to the ultrasonic waves. This is similar in concept to a turntable in a microwave oven. By moving the food , it is exposed more evenly to the microwaves, and is heated more evenly. By moving the parts you are cleaning in an ultrasonic cleaner, they are exposed to ultrasonic waves more evenly which leads to evenly-cleaned parts with more consistent results.

How Agitating Parts Washers Prevent Damage

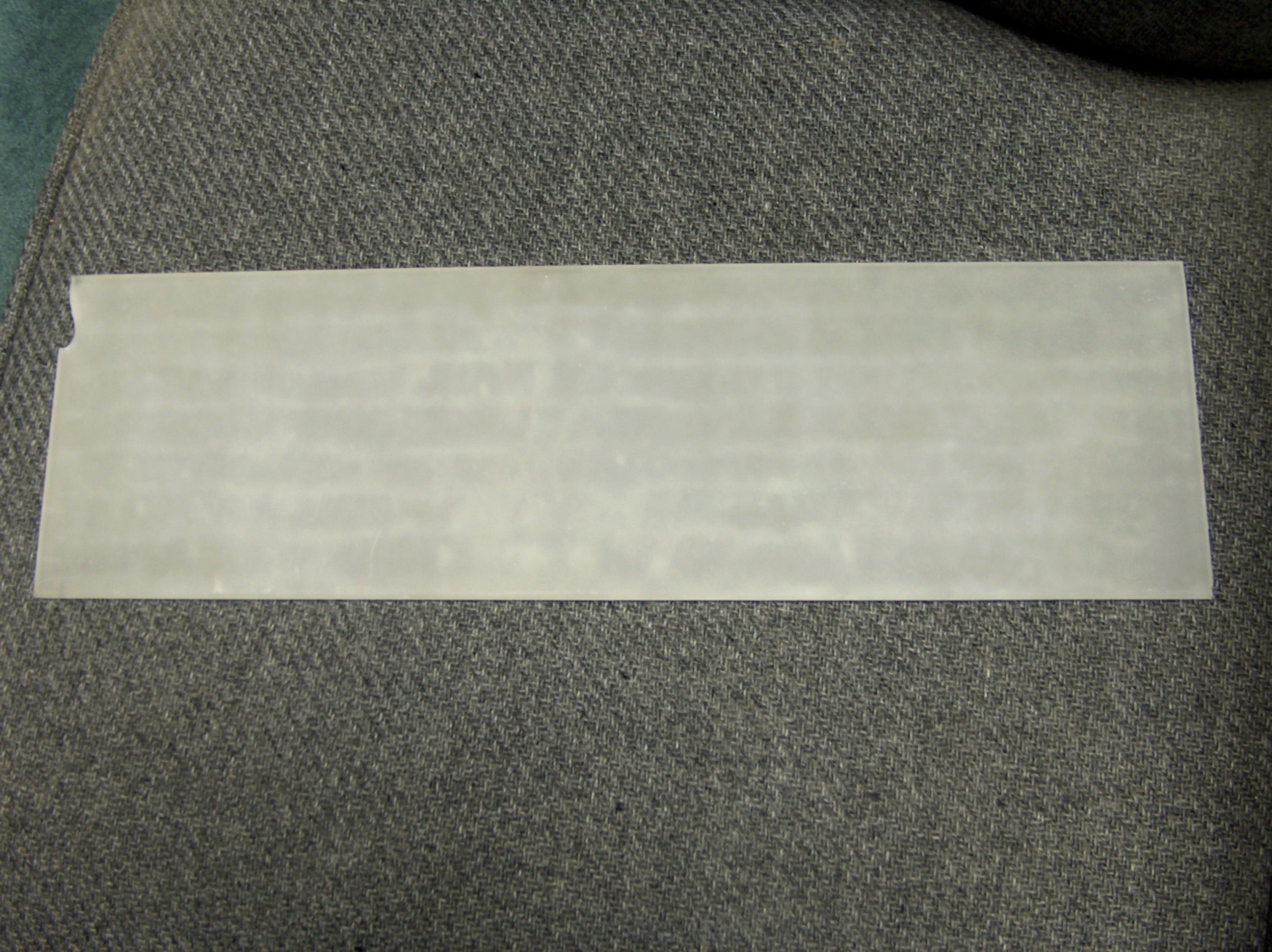

The scrubbing force at the hotspots is significantly more powerful than the areas between them, and over time this may begin to damage the parts. This is not as uncommon as you might have heard, especially at lower frequencies such as 25kHz or frequencies near 25kHz. The neighboring photo shows a glass plate that was damaged in a 40kHz ultrasonic cleaner when the part was not being agitated. Can you see the lightly colored stripes on the surface? This is the standing wave pattern produced in a 40kHz system, and has actually etched the surface of the glass. This should give you an idea of how aggressive an ultrasonic cleaner can be. Agitating parts washers would have prevented this damage. The hotspots would not have remained stationary at these locations for long enough to create the damage.

Before Zenith invented the Ultraprobe Testing Device, it was thought that a Sweep Frequency Circuit could eliminate ultrasonic hotspots, and prevent the damage shown in the photo. The truth is, it does nearly nothing to prevent such damage or eliminate ultrasonic hotspots, even though all ultrasonic cleaners include the circuit.

How Agitating Parts Washers Clean Detailed Areas Better

An ultrasonic cleaner removes dirt by breaking it away from the surface a very small bit at a time. They do not blast the dirt away forcefully. When dirt is trapped inside of blind holes or other areas that can trap it, the dirt is loosened but might remain trapped in the area unless it is flushed away by agitation. This flushing action is improved greatly if the parts are passed through the surface of the liquid, and is the reason why all Zenith agitating parts washers have this capability.

See our Benefits of Oscillation page for additional details about how oscillation improves the vast majority of ultrasonic cleaning applications.

Several Types of Agitating Parts Washers are Available at Zenith

Many systems that Zenith manufactures can include agitation to provide all of the benefits detailed above, and include the following:

- Table-top Ultrasonic Cleaners with Agitation.

- Large Single-tank Cleaning Consoles.

- Multi-stage UItrasonic Cleaners.

- Any system which includes our ADVANTAGE Automation System.