For over 80 years, Zenith Ultrasonics has designed equipment around one principle: results that meet specifications and exceed expectations. We understand what it takes to engineer an ultrasonic cleaning process that aligns with stringent product requirements, because we’ve spent decades fine-tuning the variables that affect cleaning performance.

Over time, we’ve learned what steps often go unaddressed in ultrasonic cleaning and why it’s not enough to simply build a machine that looks the part. Here are the most commonly overlooked factors that we account for in every system we build.

Air Entrapment: The Invisible Barrier to Cleanliness

Air entrapment is one of the most common causes of incomplete cleaning. When air gets trapped in blind holes, threads, or crevices, it acts as a barrier that ultrasonic energy cannot penetrate. As a result, contaminants remain in place, unseen and often undetected until later stages of production.

Zenith meets this challenge from both a design and process standpoint. By engineering programmable agitation that oscillates parts vertically through the tank, trapped air is displaced more effectively. This movement, especially when it includes breaching the liquid surface, forces air out and allows cleaning fluid to reach every cavity. It’s a simple but critical element to any application involving complex geometries.

Energy Distribution: Reaching Every Surface

Ultrasonic energy doesn’t travel uniformly through a tank. It’s affected by basket positioning, part geometry, and reflected waves. Without consistent energy distribution, some surfaces receive less exposure than others, leading to uneven cleaning.

Zenith builds in adjustable part positioning and agitation cycles that expose every surface to sufficient energy. It’s not enough to rely on a one-time dip or static soak. The system must bring each surface into consistent interaction with the ultrasonic field. Our full explanation of ultrasonic energy distribution outlines the importance of repositioning and how Zenith systems create uniform cleaning results, even for irregular or high-density loads.

Cavitational Erosion: How to Prevent Damage While Maximizing Power

More power isn’t always better. While cavitation drives ultrasonic cleaning, excessive cavitational force can degrade or even damage sensitive parts. This is especially true for thin metals, coatings, or microfeatures that can’t withstand aggressive treatment.

Zenith evaluates every part and material type before designing a cleaning cycle. We calibrate the frequency, intensity, and duration of ultrasonic activity to clean without causing erosion. Building this consideration into both hardware and software enables us to balance effective contaminant removal with long-term part integrity. Read more about how we mitigate cavitational erosion while maintaining cleaning strength.

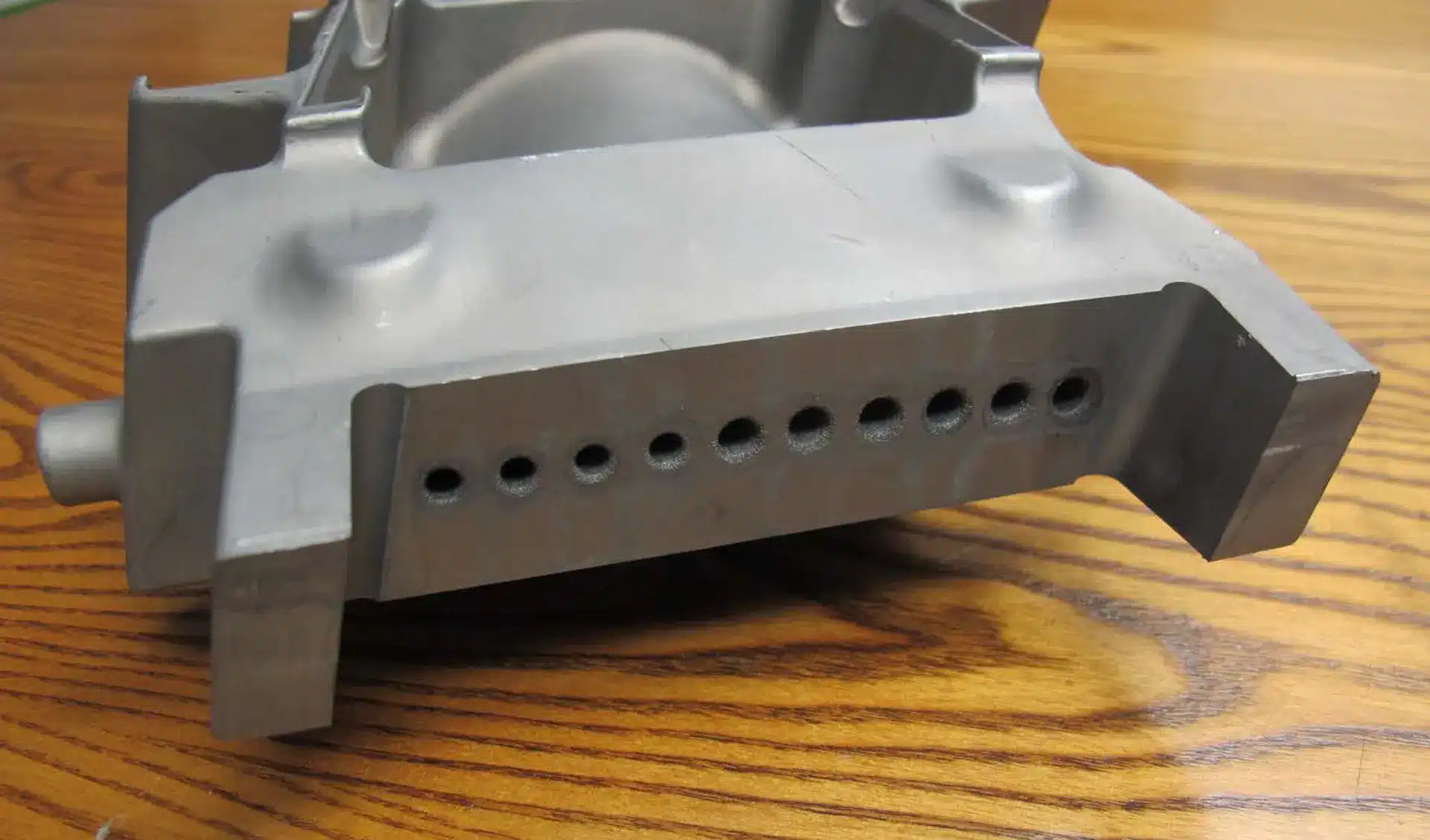

Blind Holes: A Known Pain Point, Addressed by Design

Blind holes are among the most persistent cleaning challenges. Debris, oils, or particulates can get trapped in these recesses and resist removal, especially if fluid stagnates inside the cavity.

Zenith’s cleaning process deliberately replicates a rinse-and-drain effect, moving parts vertically through the fluid to flush contaminants out. This motion forces spent fluid from the blind hole, pulling in fresh fluid and ultrasonic energy. When paired with targeted repositioning and part orientation, this approach vastly improves cleaning in recessed or partially enclosed features. Explore the details of cleaning blind holes and how Zenith systems are configured to clear them thoroughly.

Part Positioning: Why It’s Not a Set-It-and-Forget-It Variable

In ultrasonic cleaning, how a part is positioned affects more than just access. It shapes the interaction between ultrasonic waves and the part surface. Poor orientation can trap air, block fluid flow, or reflect energy away from key areas.

Zenith allows operators to reposition parts throughout the cleaning cycle, either manually or through programmed intervals. This helps ensure that even hard-to-reach areas are eventually exposed to peak cleaning energy. In many applications, lifting the basket, rotating the part, and resuming the cycle multiple times produces dramatically better results than static submersion.

Ultrasonic Theory Meets Industry Application

Cleaning quality starts long before the tank is filled. Zenith’s systems are engineered to account for real-world variables that affect how ultrasonic energy interacts with each part. From tank design to process controls, every system is customized to reduce risk, improve consistency, and help manufacturers meet their most demanding standards. If you’re looking to improve cleaning outcomes while protecting part integrity, contact our engineering team today.