Brass Cleaning Considerations

Brass cleaning using ultrasonics requires special considerations to ensure satisfactory results. These considerations include:

- Brass-safe or multi-metal cleaning fluids.

- Limited exposure to deionized water.

- Use of proper ultrasonic frequencies to prevent damage.

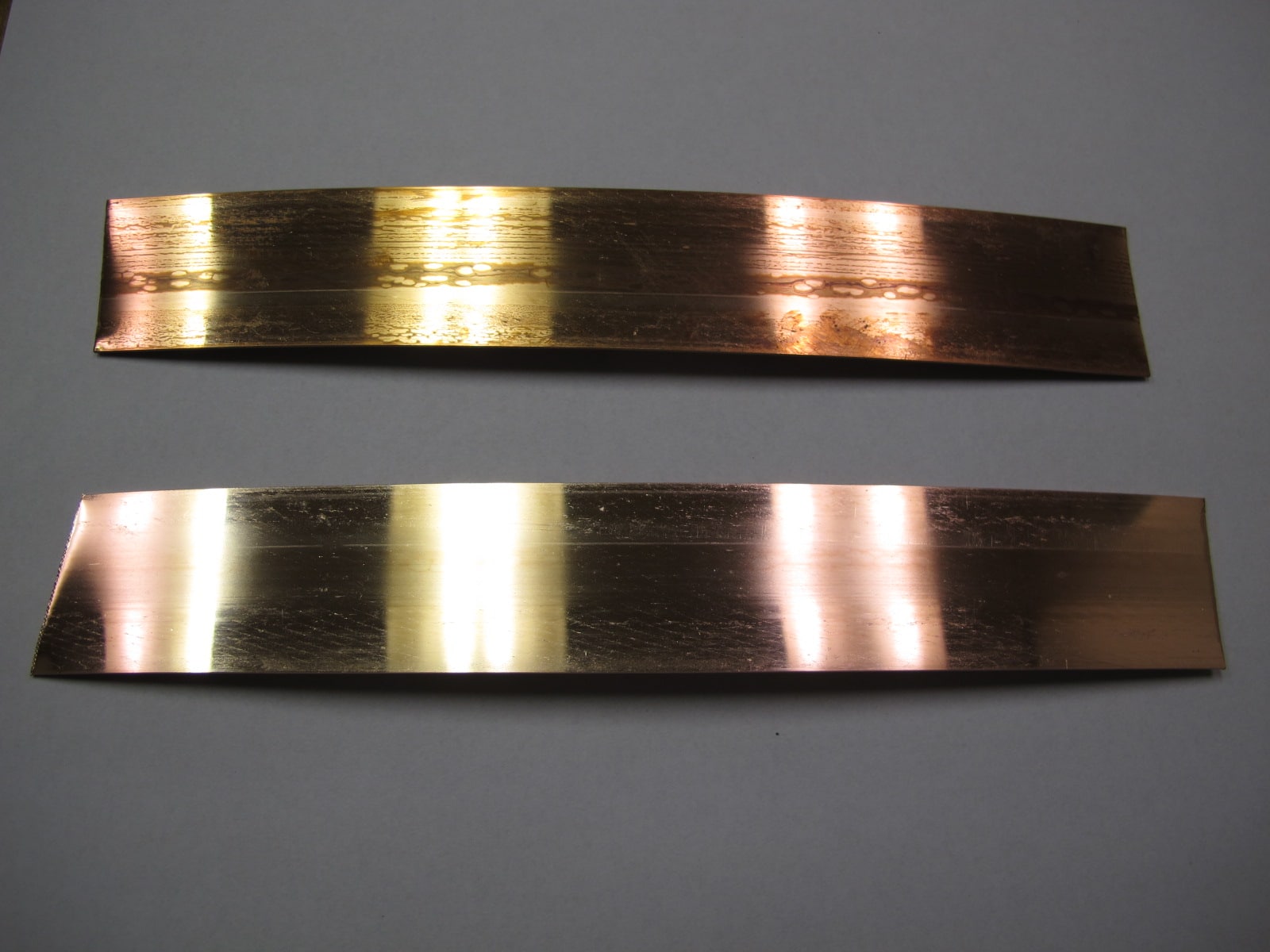

The use of cleaning fluids which do not discolor the brass is essential, and many such cleaners exist. Zenith’s Agent ACS is one such cleaner, and includes the ingredients to not only prevent discoloration but also brighten the brass.

Although deionized water is used to prevent water spots on parts, the amount of time that the brass is exposed to deionized water must be limited to prevent darkening or discoloration of the material

Ultrasonic frequency selection is crucial to prevent etching or damage of the brass. This is especially important on machined or highly-polished materials.

CROSSFIRE Multiple Frequency Ultrasonics / the Best Choice for Brass Cleaning

Zenith’s patented CROSSFIRE Multiple Frequency Ultrasonic System is especially suited for the cleaning of brass due to its inherent reduction in damage potential on softer and polished metals. The 40/80kHz CROSSFIRE system has been shown to be 16x less damaging to parts when compared to single-frequency systems operating at 25kHz or 40kHz systems.

With over 85 years of experience manufacturing cleaning machines, Zenith can provide a system that can ensure that your cleaning application is a success.