Benefits of Ultrasonic Cleaning when Compared to Other Technologies

There are numerous benefits of ultrasonic cleaning, and it is perhaps the single most effective cleaning method for metal parts. Results obtained cannot be compared to other part cleaning technologies, such as spray washers or oscillation parts washers which are not equipped with ultrasonic components. Although the largest benefit is the level of cleanliness which can be achieved, other benefits when compared to spray washers include:

- Spray washing systems are “line of sight” cleaners. The only part areas which are effectively cleaned are those which are directly attacked by the spray action, although lighter contaminants may be flushed away in the absence of direct spraying action.

- Since many parts include bends, blind holes, and detail which is difficult or impossible to reach effectively with spray action, these part designs will not be effectively cleaned in a spray washing system, even those equipped with turntables or moving spray heads.

- Spray washing systems also require significantly more maintenance, and cost more to operate due to the evaporation of water which is common to these systems.

- Cleaning fluid temperatures are also typically higher in these systems, and heat is very expensive to generate electrically.

- Spray nozzles must also be periodically removed and cleaned to ensure the best possible cleaning results.

Benefits when Compared with Oscillation Parts Washers

Another common parts washing method, an Oscillation Parts Washer, involves the oscillation of a parts load within a heated cleaning fluid, and, in some cases, the addition of Spray Under Submersion or turbulence produced by high pressure pumps. Oscillation washers have the following drawbacks:

- Although these cleaning methods can be effective at removing light oils, shop contaminants, metal chips that are resting on the surface, coolants and other similar contaminants.

- Oscillation washers are not as effective at removing bonded contaminants, or contaminants which are thicker and more difficult to remove.

- Oscillation washers are also marginally effective when cleaning parts with internal detail which blocks the cleaning fluid from circulating.

- Oscillation washers rely heavily on the effectiveness of the cleaning fluid to remove more stubborn contamination

- Differences in contaminant levels between parts can affect the consistency of the cleaning results.

Ultrasonic Cleaners Overcome Drawbacks of Other Technologies

Ultrasonic cleaners overcome the drawbacks of both spray washing systems and oscillation cleaning systems. Their properties include:

- Ultrasonic cleaning systems have the capability to clean inside of holes the size of a human hair and smaller and penetrate into the microscopic detail on the part surface.

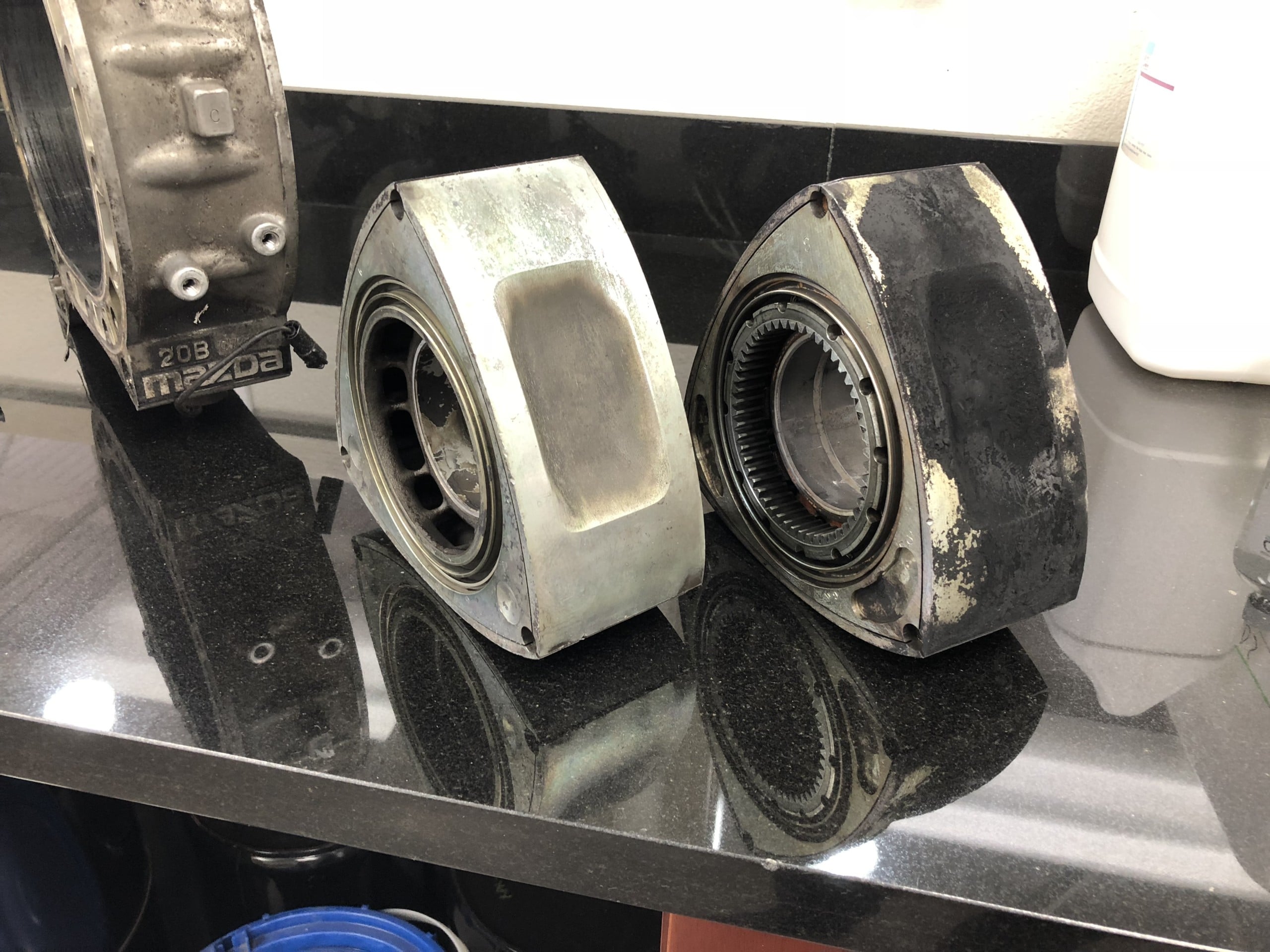

- Ultrasonic cleaners also have the ability to clean the INSIDE of objects which can not be cleaned using spray or oscillation methods, such as the inside of tubing, injection mold gas cavities and channels, carburetors, complex solenoid valves, and other similar part designs.

- Ultrasonic cleaners can remove the toughest of contaminants when used with the appropriate cleaning agents.

Easy maintenance. Oscillation and spray washing systems traditionally require more maintenance. - More consistent cleaning results: Since the surface of the parts are being scrubbed microscopically, performance is not greatly affected by differences in contaminant levels or types.

In virtually every application, the benefits of ultrasonic cleaning far outweigh the performance one can expect from other cleaning technologies.