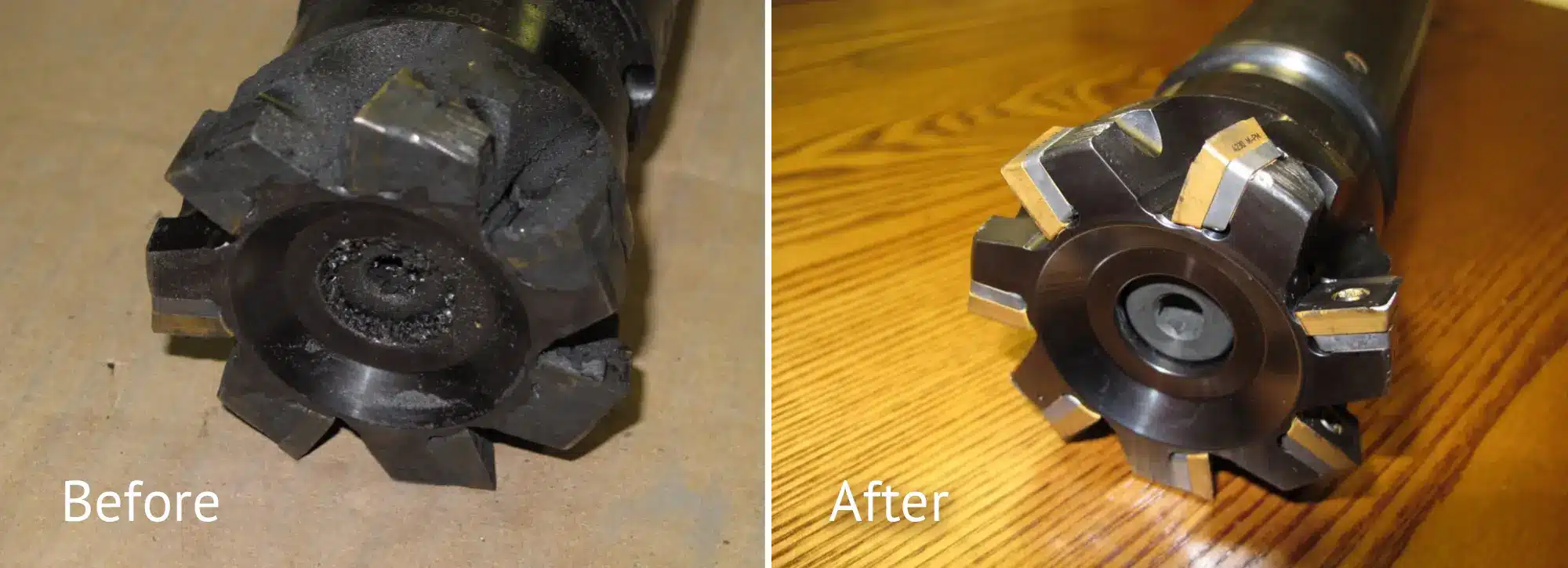

In high-volume manufacturing, few things are as fundamental—and as underestimated—as tool cleanliness. For a major U.S. equipment manufacturer, that principle was being tested. As part complexity increased and production volume grew, their manual, solvent-based cleaning process could no longer keep up. Cleaning quality was inconsistent, labor costs were high, and solvent use raised operational concerns. Despite being a household brand name, the manufacturer was internally grappling with poor cleaning outcomes, tool wear, and quality risks that couldn’t be ignored.

Contaminated cutting tools don’t just slow down production; they also introduce the potential for dimensional inaccuracies, rough surface finishes, and long-term machine damage. With thousands of cycles running daily, even small issues can escalate quickly. To move forward with confidence, the manufacturer required a solution engineered for repeatability, volume, and precision.

A Common Need with Uncommon Demands

On the surface, the customer’s needs were familiar: clean a high volume of metal tools coated in oils, greases, and machining fluids. But beneath the surface, the situation was more involved. The parts were heavy—up to 500 pounds per batch—and needed to be cleaned in a near-vertical orientation.

Part orientation plays a critical role in ultrasonic cleaning. When tools are positioned upright and tightly spaced, it can disrupt the flow of cleaning fluid and scatter ultrasonic energy, leaving certain surfaces underexposed. Zenith’s engineers carefully modeled spacing and suspension geometry to avoid dead zones and maintain acoustic access to every surface, including recessed and shielded areas. The custom system had to clean each part thoroughly, cycle after cycle, without relying on manual intervention or repositioning.

Turning Limitations into Innovation

We began with a base concept: a proven multi-stage ultrasonic cleaning, rinsing, and drying system for a wide range of industrial applications. But instead of steering the client toward a pre-configured model, we worked from their exact requirements to design and deliver a custom system. We adjusted tank dimensions to avoid unnecessary over-sizing. We designed a right-angle conveyor to integrate with the facility’s layout, with agitation methods tailored to the part geometry and type of contamination. We also fine-tuned tank volume, ultrasonic watt density, and fluid turnover rates to maintain consistent energy delivery across the load, so even the heaviest tools receive uniform cavitation exposure without compromise.

Many of our systems start with our proven platform, then evolve based on real-world use cases. In this project, that meant offering modified tank sizes that delivered performance without pushing the customer into a larger, costlier build. It also meant clearly communicating trade-offs—like balancing tank size against throughput or structural complexity against budget. It’s how we approach customization: not as a premium feature, but as a practical engineering process grounded in transparency and collaboration.

Engineering Achievement

In ultrasonic cleaning, part agitation helps dislodge tough contaminants and improve rinse quality. But when cleaning heavy loads, agitating the parts without disrupting ultrasonic performance becomes a challenge. Traditional systems rely on support structures beneath the load, but in ultrasonic environments, anything submerged in the tank can interfere with the energy field. Basket frames, fixtures, and mechanical supports all absorb and scatter ultrasonic waves, reducing the cavitation intensity delivered to the parts themselves.

To meet the challenge with a solution, we developed a new agitation system that supports the basket from above, removing all unnecessary structures from the tank. The design allows for mechanical oscillation of the load at a tuned frequency, improving solution exchange across every part surface while preserving the full energy profile within the tank. The impact on cleaning performance was immediate and measurable.

That advancement would later become the Advantage Automation System. By solving a load-specific interference issue, we unlocked a modular automation approach that now supports a wide range of parts, tank sizes, and contamination profiles.

Ease Built In

Despite the complexity and customization, the final system arrived plug-and-play ready. Our team configured every peripheral for quick setup and programmed the system controls to match the customer’s cleaning cycle parameters, using onboard diagnostics and programmable logic controllers (PLCs) to support both reliability and ease of use.

While many manufacturers offer custom systems, few provide user-centric documentation and support. Every Zenith manual includes photos of the actual unit delivered—not a stock version—so operators and maintenance teams can easily locate components and follow procedures with confidence. It’s one more way Zenith makes industrial-scale innovation more accessible.

A New Standard for Ultrasonic Cleaning

Solving a specific cleaning challenge led to something far more enduring. By rethinking how heavy parts could be agitated and cleaned without compromising ultrasonic energy, we created a solution that now serves a much broader range of industrial applications.

Today, the Advantage Automation System is one of our most widely adopted platforms. It’s trusted by manufacturers that need reliability, efficiency, and technical depth in every cleaning cycle. What began as a highly tailored design now powers operations across industries, part types, and production environments. It’s the difference between getting a machine and getting the right machine. Learn more about our customizable Advantage Automation System and request a complimentary demo cleaning.